Made from up to 100% recycled plastic

Films made from used plastic are produced from either PIR (post-industrial recycling) or PCR (post-consumer recycling) and therefore offer an ideal alternative to conventional LDPE bags.

Individually printable

Our films can be printed according to your wishes. For example, you could print your own logo, pattern, image or other. Our staff will be happy to provide you with the best possible advice. This way we can ensure that you get exactly what you want. Of course, our bags are also available in an unprinted version. This, as well as custom printing, is only possible from a certain minimum order value.

Cost-effective

Due to the proportion of recycled materials, film made from used plastic is a cost-effective alternative.

Our logo for used plastic

With our "Made with recycled plastic" icon, you can draw attention to the sustainable properties of the film.

Many dimensions in stock

We can offer you many different sizes of flat and pressure seal bags from stock. But of course we can also produce films and bags according to your individual requirements.

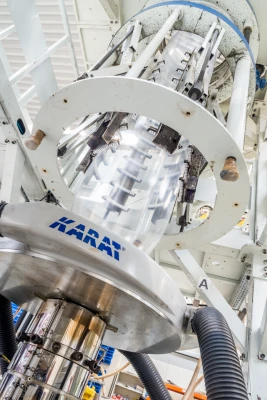

The recycling process at a glance

Our in-house recycling machine forms the basis for the production of film from used plastic. This converts used film and film waste into recyclable granulate.

The process begins with the introduction of the used films, followed by precise shredding. The films are melted down to their original form. The resulting granulate can then be reused for the production of new films.

This process actively contributes to reducing environmental impact and promotes the sustainable use of resources.

You can find a graphic representation of the regranulation process under the following link.

Possible applications

Sustainable shipping packaging

Recycled plastic bags, even if not food-safe, offer an environmentally friendly solution for the shipping sector. Companies can use recycled material to package their products safely and at the same time fulfil their ecological responsibility.

Industrial storage and transport

In industries such as electronics or mechanical engineering, used plastic bags are ideal for protecting components from dust and moisture during storage and transport. This promotes efficient storage and reduces the risk of damage.

Cost efficiency in product packaging

Non-food-safe recycled plastic bags offer a cost-effective packaging option for companies, especially in areas where food contact is not relevant. This enables cost savings while at the same time taking environmental aspects into account.

Sustainability in the fashion industry

Recycled plastic bags are popular in the fashion industry as packaging for textiles and accessories. Companies can use recycled materials to safely package fashion products while promoting sustainable practices.

Your partner for packaging for over 50 years

As a manufacturer of films, we produce a wide range of film products, starting with the processing of granulate through to the production of the final films in our own facilities. The needs of our customers are at the centre of our efforts.

Joint planning and the joint search for solutions to challenges not only ensure trust, but also form the basis for a long-term partnership.

Using state-of-the-art extrusion equipment, we produce films in various forms, including flat film, tubular film, semi-tubular film and gusseted film. Our production includes a variety of raw materials, including LDPE, HDPE, MDPE and bioplastics. Further processing into bags takes place in our converting department, which enables a wide range of attractive product options.

Do you want to stand out from the crowd?

Have packaging printed now and stay in the customer's memory with a striking print. Customised printing is possible in multiple colours and in any size.

FAQ - Frequently asked questions