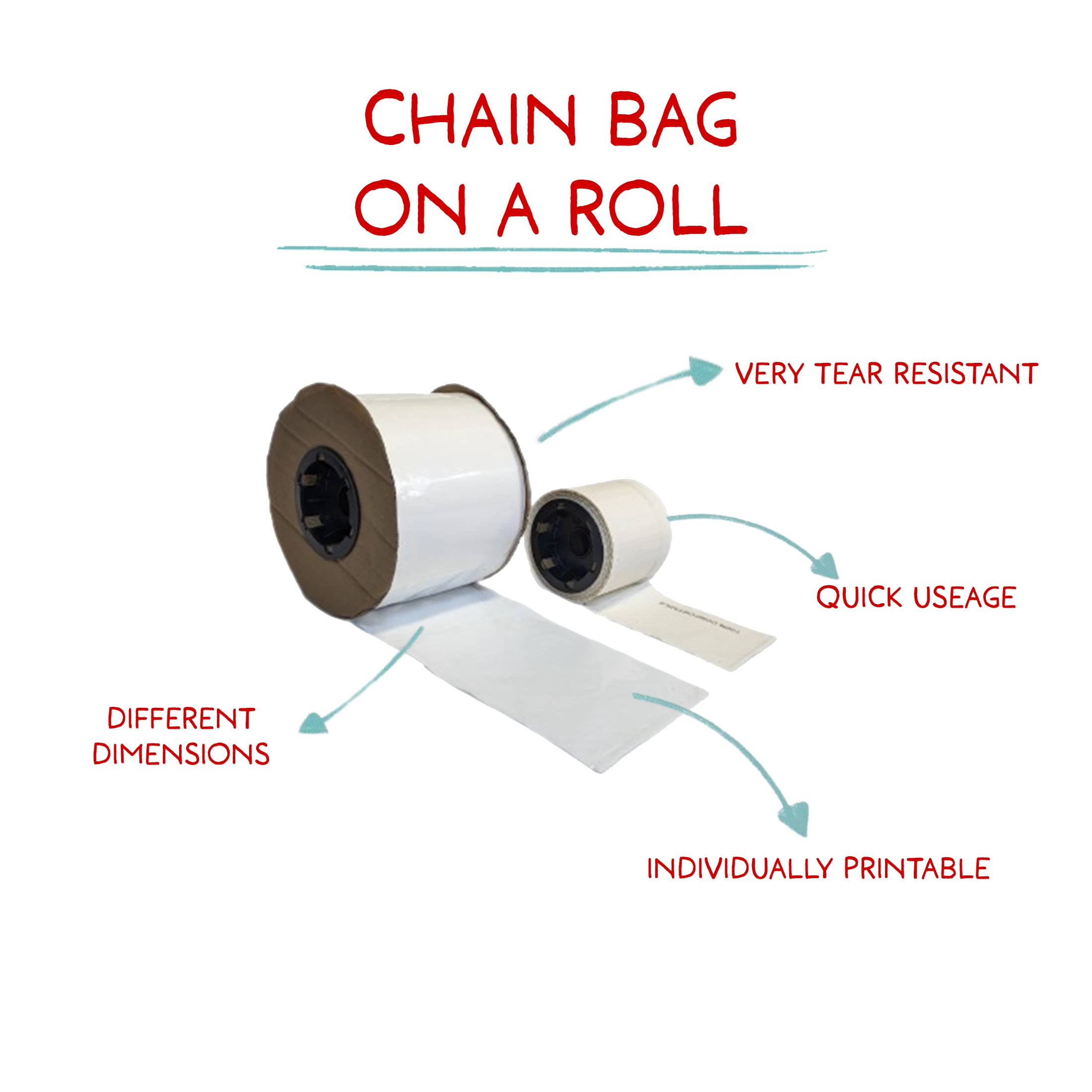

Delivery on Roll

Chain bags are delivered on rolls, meaning they are not individual bags but rather a continuous chain of connected bags. This facilitates their handling and enables efficient filling.

Tear-off Perforation

Each bag in the chain is connected to the next via tear-off perforation. This allows for easy and clean separation of the bags from each other without the need for scissors or other tools.

Side-Mounted Cardboard Discs

To ensure precise and even unrolling of the bags from the roll, side-mounted cardboard discs are attached. These ensure that the bags do not jam or tangle during unrolling.

One-Sided Pre-Opening

Chain bags feature a one-sided pre-opening, allowing them to be easily opened either manually or by a burst of air. This facilitates filling the bags, even while they are still on the roll.

Chain Bags & Roll Bags

Chain or roll bags are packaging bags delivered endlessly on a roll, interconnected by tear-off perforation. They ensure smooth unrolling facilitated by side-mounted cardboard discs.

Filling is done by manually opening the one-sided pre-opening or by a burst of air while the bags are still on the roll. After filling, the bag is separated from the roll along the tear-off perforation and sealed. Upon request, chain bags are supplied with pre-punched holes to allow air to escape during filling.

Pre-opened chain bags find application in various industries including automotive and toy industries, manufacturers of sanitary products and metal goods, the electrical and electronics sector, as well as the chemical, pharmaceutical, and medical technology fields.

Applications

Machine Processing

Chain bags can be efficiently processed by automatic packaging machines. These machines pull the bags from the roll, open, fill, and seal them in a continuous workflow. This allows for high speed and accuracy in packaging. Automated packaging lines can increase productivity and reduce operating costs.

Manual Processing

Chain bags can also be processed manually, providing flexibility and easy handling. Employees can separate, open, fill, and seal the bags from the roll. Thanks to the one-sided pre-opening, the bags can be easily opened either by manually pulling at the pre-perforation or by a burst of air. This flexibility enables efficient use even without automated packaging machines, especially for smaller production facilities or specialized packaging tasks.

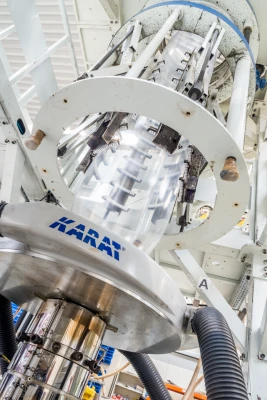

Your Partner for Packaging for Over 50 Years

As a manufacturer of films, we produce a wide range of film products, starting from processing granules to the production of final films in our own facilities. The needs of our customers are at the center of our efforts.

Collaborative planning and joint search for solutions to challenges ensure not only trust but also form the basis for a long-term partnership.

By using state-of-the-art extrusion plants, we produce films in various forms, including flat film, tubing film, semi-tubing film, and gusseted film. Our production encompasses a variety of raw materials, including LDPE, HDPE, MDPE, and biofilms. The processing into bags is done in our finishing department, which offers a wide range of attractive product options.

Want to Stand Out from the Crowd?

Get your packaging printed now and stay in the minds of customers with striking prints. Custom printing is available in full color and any size.

FAQ - Frequently Asked Questions