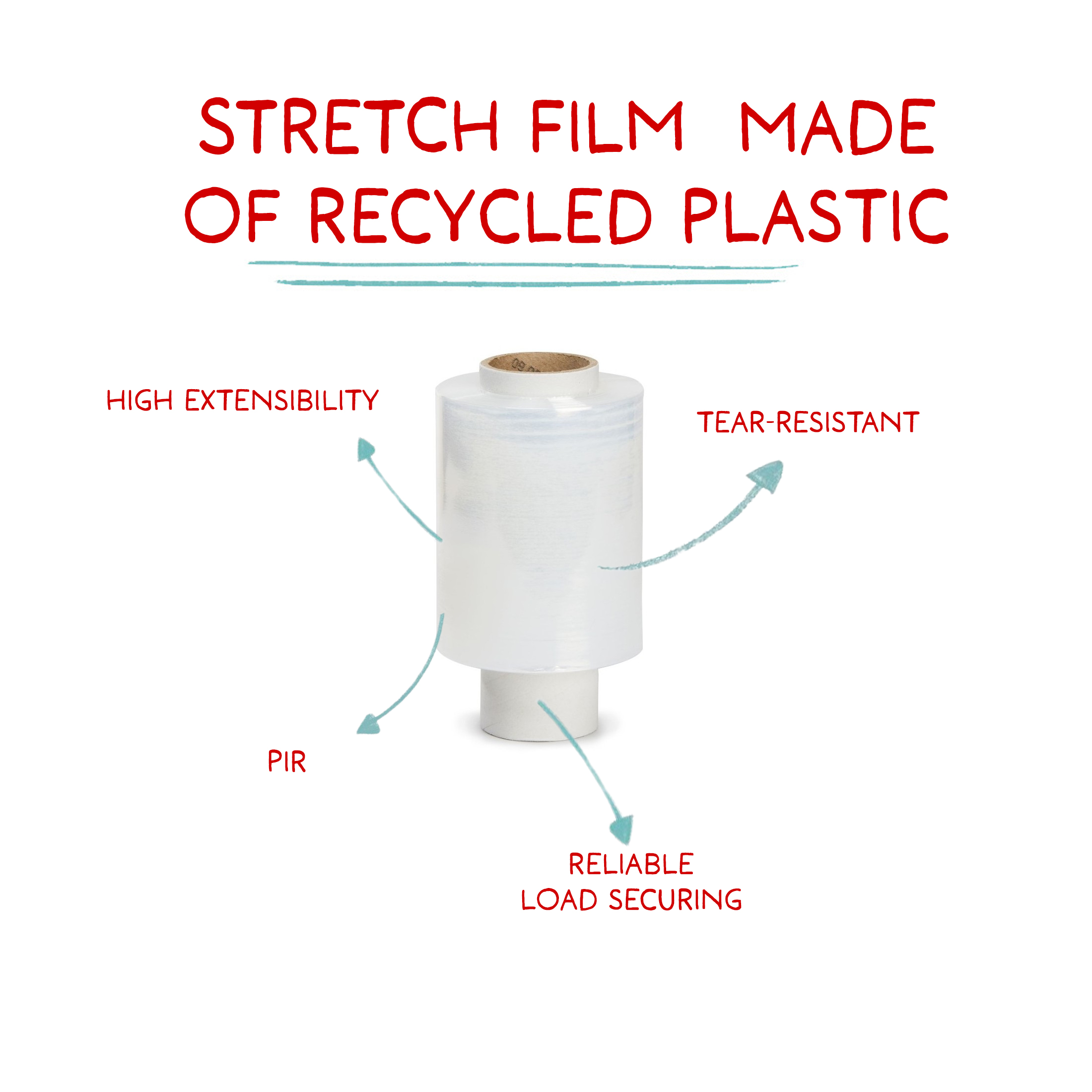

High Stretchability

Stretch film made from recycled plastic offers high stretchability, indistinguishable from conventional stretch film. This environmentally friendly option enables flexible packaging solutions for various goods.

Tear Resistant

Stretch film made from recycled plastic not only impresses with its high stretchability but also with its impressive tear resistance, which is on par with conventional stretch film.

Reliable Load Securing

Stretch film plays a crucial role in securing loads during transportation. With its high stretchability and tear resistance, it provides reliable fixation of goods on pallets. This minimizes damages and losses while ensuring efficient logistics.

Made from Up to 100% Recycled Plastic

Our stretch film made from recycled plastic is manufactured from a high-quality recycled material, consisting of up to 100% recycled plastic. This recycled plastic is carefully extracted from waste and subjected to an efficient recycling process. By using recycled material, we make a significant contribution to reducing environmental impact and conserving natural resources.

By converting recycled plastic into stretch film, we not only offer an innovative packaging solution but also make a clear statement for sustainability and environmental protection. Our product is an environmentally friendly alternative to conventional packaging materials, enabling companies to reduce their ecological footprints.

Furthermore, our stretch film made from recycled plastic offers the same excellent properties as conventional stretch film. It is highly stretchable, tear-resistant, and provides reliable load securing during transportation.

Companies can thus not only act environmentally responsibly but also benefit from the practical advantages of our sustainable packaging solution.

Applications

Pallet Stabilization

Machine stretch film ensures efficient fixation of goods on pallets, stabilizes loads during transportation, and minimizes the risk of damage due to shifting. This ensures a secure supply chain and storage.

Product Bundling

Precise wrapping with machine stretch film reliably bundles products. This not only increases efficiency during shipping but also enables an attractive presentation in retail by securely holding products together.

Long-term Storage

Using machine stretch film protects goods from dust, moisture, and other environmental influences during storage over extended periods. This helps maintain product quality and minimize waste.

Theft Prevention

Machine stretch film serves as an effective protective layer, securing products against unauthorized access. By tightly wrapping packaging units, theft prevention is enhanced, and the integrity of the supply chain is strengthened.

Your Partner for Packaging for over 50 Years

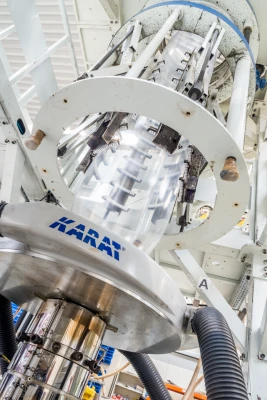

As a manufacturer of films, we produce a wide range of film products, starting from processing granules to manufacturing the final films in our own facilities. The needs of our customers are at the center of our efforts.

Joint planning and collaborative search for solutions to challenges not only ensure trust but also form the basis for a long-term partnership.

With the use of state-of-the-art extrusion equipment, we produce films in various forms, including flat film, tubular film, semi-tubular film, and gusseted film. Our production includes a variety of raw materials, including LDPE, HDPE, MDPE, and biofilms. The processing into bags is done in our packaging department, which enables a wide range of attractive product options.

Want to Stand Out from the Crowd?

Now get your packaging printed and stay in the minds of your customers with striking prints. Custom printing is available in full color and any size.

FAQ - Frequently Asked Questions