welding equipment

Welding equipment for any films that protect your products from dust and contamination during storage and transportation by welding.

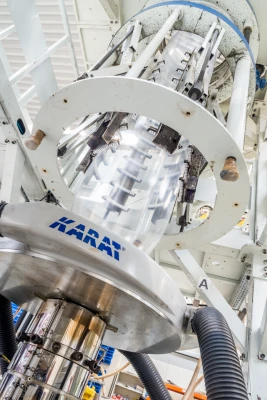

120 GE Tong Welder

Welding guns are suitable for welding goods of any size. The flexible handling and the comparatively low weight allow a trouble-free operation. Welding guns are immediately ready for use and very reliable and work according to the heat pulse method. An adjustable gun contact pressure enables constant welding results.

You can access the data sheet via the following link.

Special features

- Double pulse heating with 3 mm weld seam width

- Acoustic error signal when the push button is pressed too briefly

- Independent control of the heating band temperature

- Adjustable gun contact pressure = constant welding result

- Automatic tension compensation for different seam lengths of the guns

Usage

The welding pulse is triggered by a pressure switch after the material is inserted. The welding process takes place automatically. The welding time is preselected on the rotary potentiometer. The expiration of the welding time is controlled electronically.

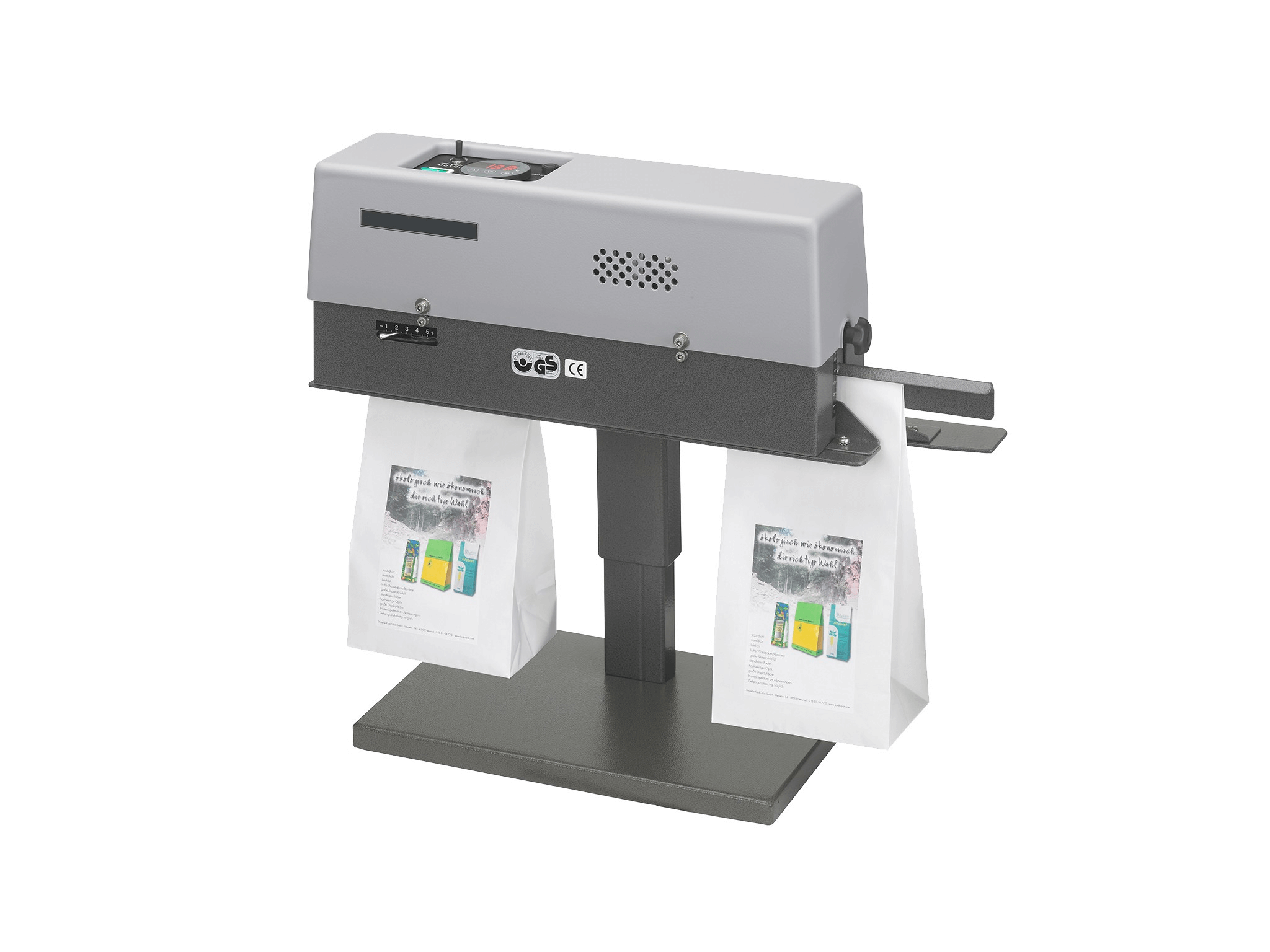

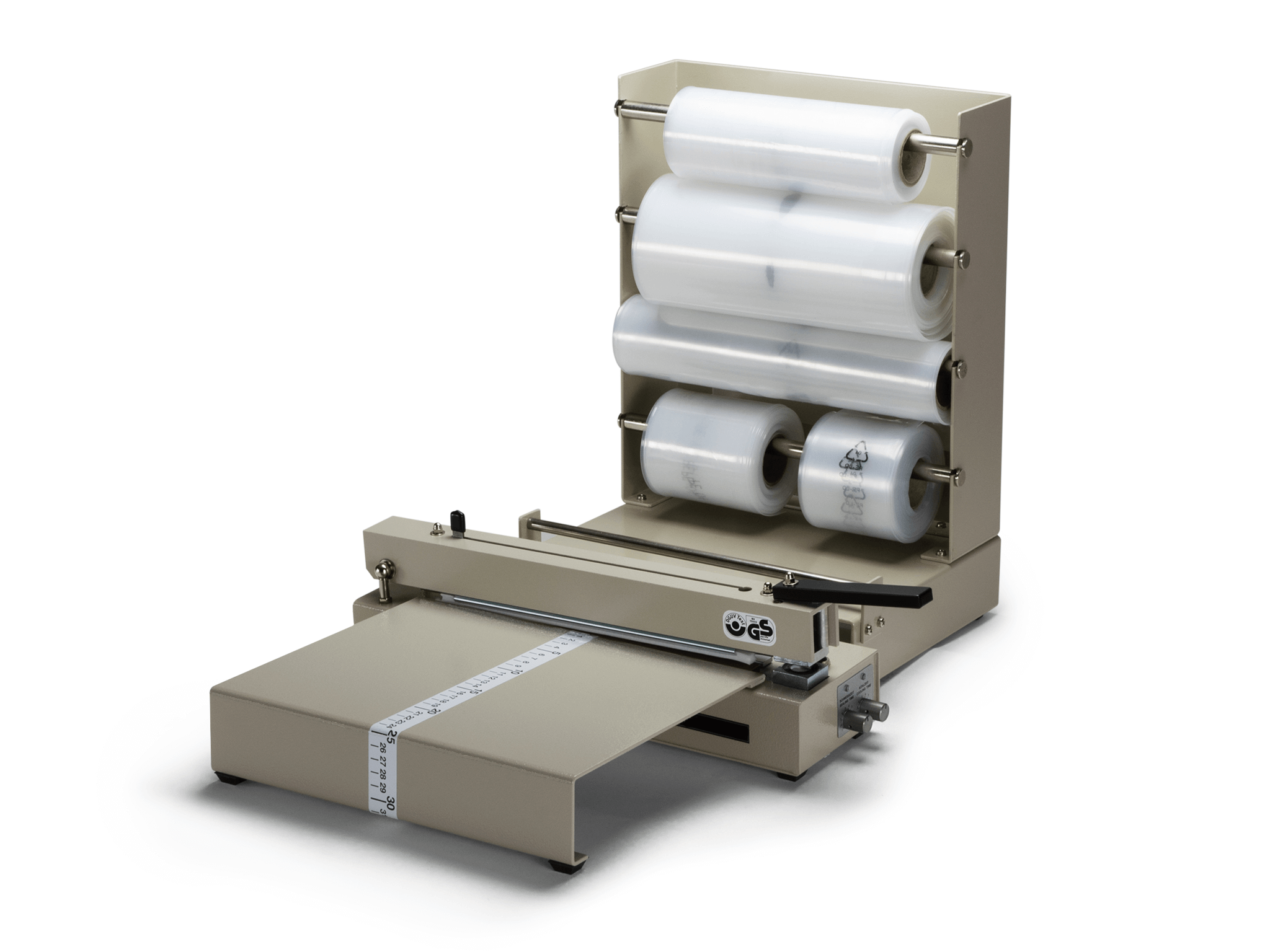

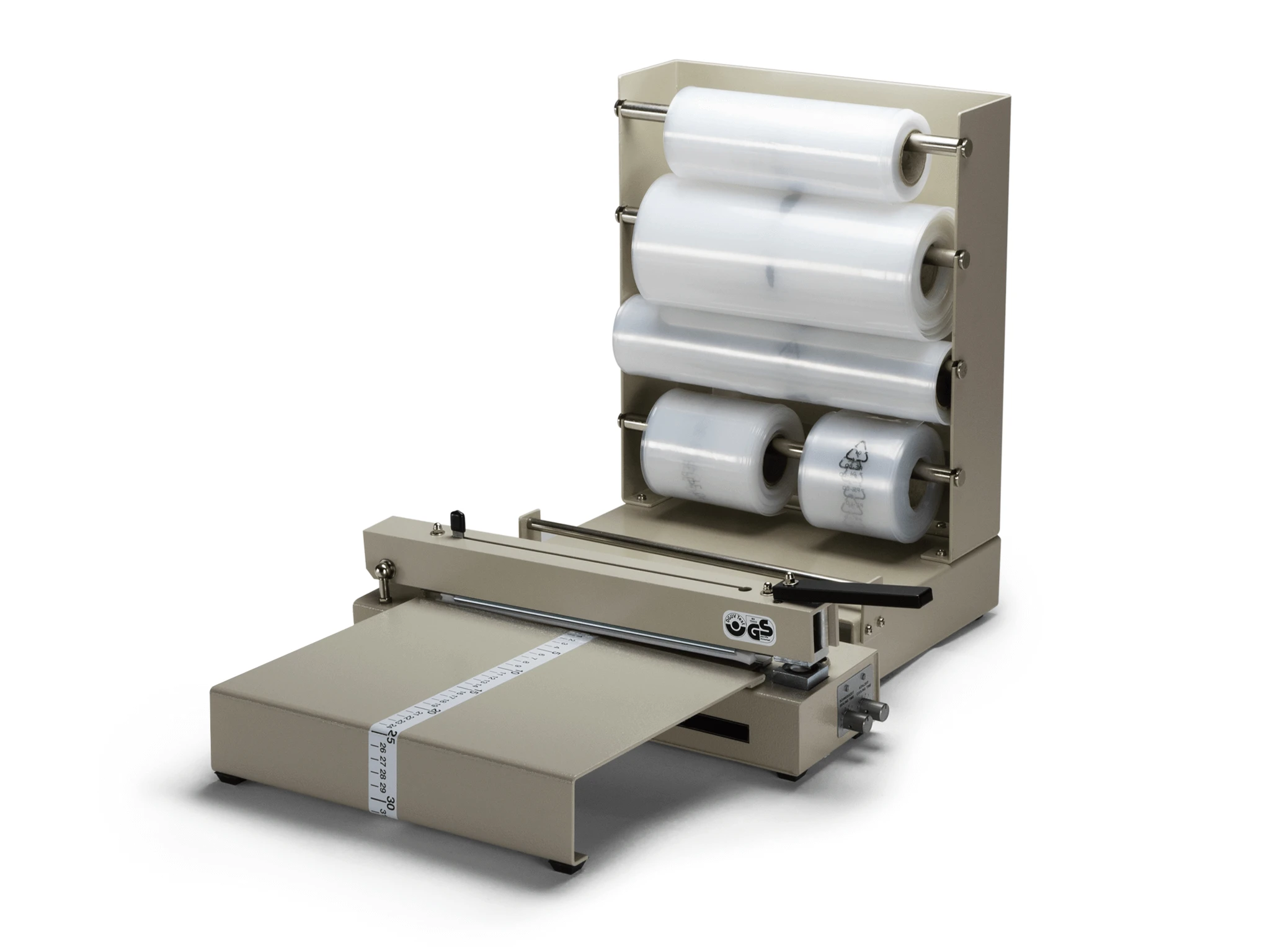

240 + 240 M-Series bench welder

Table welders are easy to handle and can be used immediately. The device is operated by hand and is very space-saving. The welder is suitable for welding a variety of products and creates order in your workplace.

You can access the data sheet via the following link.

Usage

After the material to be welded has been placed on the sealing bar, the sealing process is triggered by pressing down the lever arm. When the control lamp goes out, the process is completed and the cooling time phase begins.

Special features

- Heat pulse method

- automatically triggering heat pulse

- infinitely variable welding time electronics

- The M-version has an automatic cooling time control

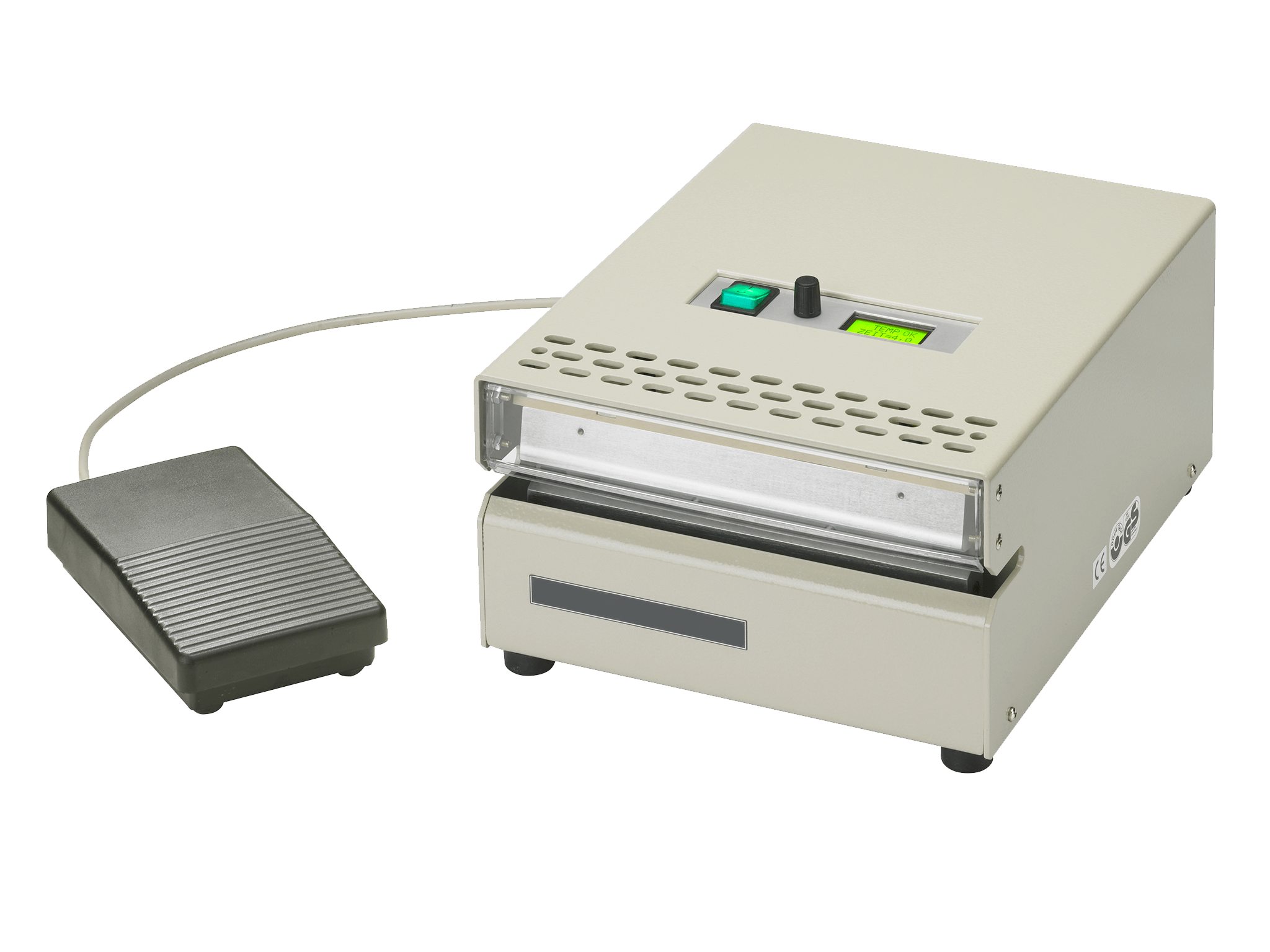

260 HSG heat sealer

The sealing device has permanently heated sealing elements. Both aluminum and paper laminates as well as PP films can be reliably sealed in pouch form.

You can access the data sheet via the following link.

Special features

- Input of parameters via a multifunction knob

- Precise temperature control

- Piece counter

- Sealing time adjustment to the tenth of a second

- Foot switch enables easy closing of the sealing elements

Usage

The sealer is suitable for continuous use. A multi-function knob allows setting the temperature and sealing time. After a short heating phase, the packaging is placed between the sealing elements. Then the foot switch must be actuated.

350 DSM-TE-Series continuous welding machine

Usage

Special features

- Carries bag weights up to 500g

- 4mm weld as standard

- Suitable for upright bag sealing

400 DSM-Series continuous welding machine

Special features

- Carries bag weight up to approx. 500g

- Suitable for upright bag sealing

Usage

400 SZ Hot sealing tongs

Usage

Special features

- Works without pulse generator

- temperature-repellent polycarbonate cover of the sealing elements

- Temperature settings between 100° C and 200° C possible

- Handle electronics allow setting of the sealing time to the second